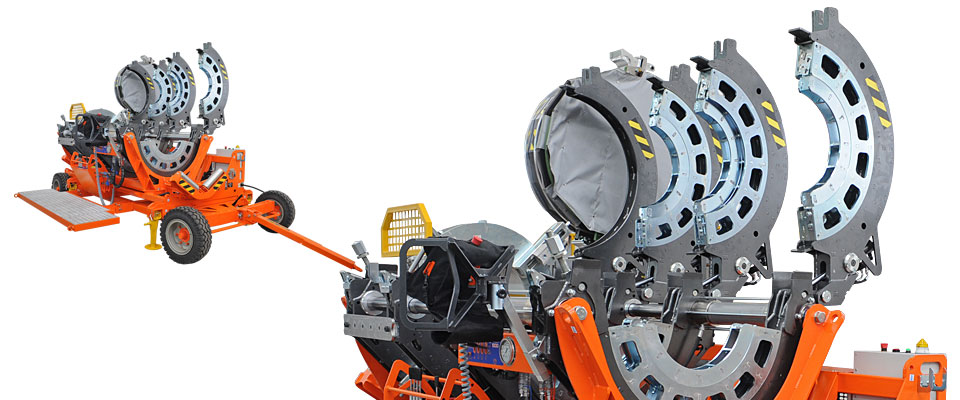

DELTA 1000 TRAILER is a self-aligning fusion machine, suitable for welding thermoplastic pipes for the transport of water, gas and other fluids under pressure, up to Ø 36" IPS/DIPS

DELTA 1000 TRAILER allows to easily weld fittings like elbows, tees, Y-branches and stub flanges.

DELTA 1000 TRAILER allows to easily weld fittings like elbows, tees, Y-branches and stub flanges.

Standard machine features:

- Machine body mounted on a 4 wheeled chassis, easily removable for working in tight spaces

- Steel hydraulic clamping with the fast-locking inserts, which allows to place and remove inserts in seconds

- Self detaching device: helps removing the heating plate during welding procedure

- Self detaching device: helps removing the heating plate during welding procedure

- 4 wheeled chassis with 2 steering wheels and a safety brake

- An on-board hydraulic electric facer that is equipped with a safety microswitch

- An on-board hydraulic heating plate Teflon-coated (PTFE) which comes with a high-temperature-proof bag,

- An EASY LIFE welding system: the operator to program and pilot all the welding cycle in an easy, fast and very intuitive way

- A control panel with a large graphic display which is also removable from the machine body to be able to weld from outside the ditch

- GPS traceability

- Data-logging system to store full welding data

- USB port

- A control panel with a large graphic display which is also removable from the machine body to be able to weld from outside the ditch

- GPS traceability

- Data-logging system to store full welding data

- USB port

- PDF files.

- Store up to 4000 joint reports

- Store up to 4000 joint reports

- Two hydraulic lateral rollers

- Control panel for hydraulic movements.

ON REQUEST (ACCESSORIES)

- Clamps’ inserts from Ø 14" IPS to 36" IPS; 14" DIPS to 36" DIPS; 335 to 900 mm

- Trolley

- Tool for flange necks

- Kit serial printer

- Kit for IN-DITCH use

- Kit hoist

DELTA 1000 TRAILER

DELTA 1000 TRAILER