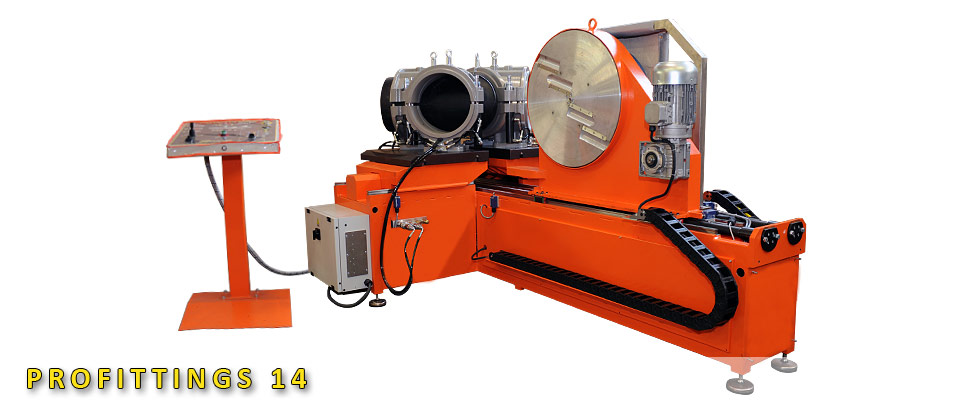

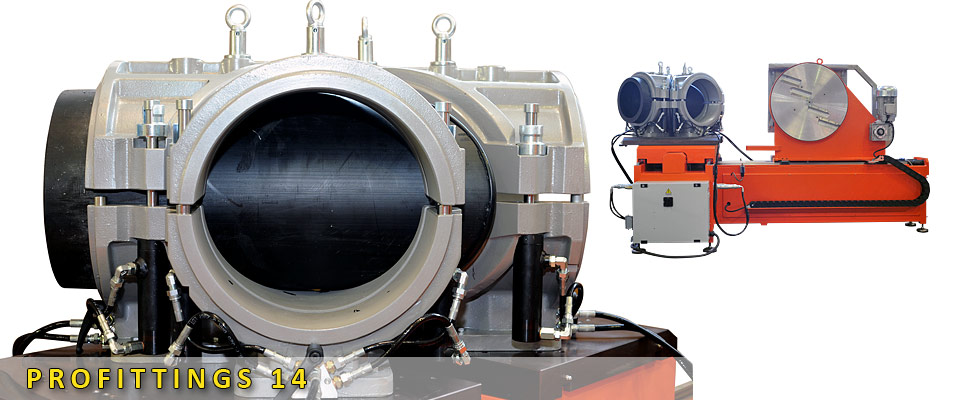

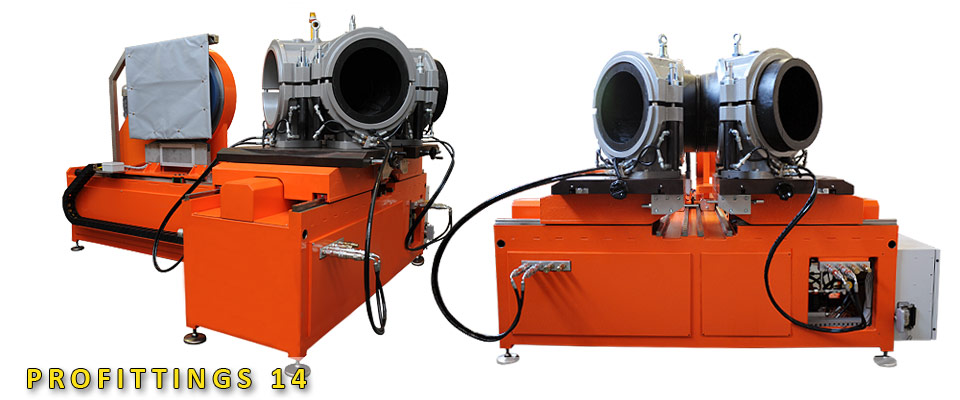

This is a workshop welding machine designed to fabricate fittings like elbows up to Ø 16" IPS, wyes (Y), tees and crosses up to Ø 12" DIPS by joining pipe segments, with the help of special jaws. Elbows and wyes (Y) jaws opening/closing and locking movements are controlled hydraulically, while tees/crosses jaws opening/closing movements are manual.

PROFITTINGS 14 can also weld special and moulded fittings such as elbows, tees and flange necks, thanks to a different type of special jaws (controlled hydraulically).

Composed of:

- A machine body with two hydraulically controlled carriages; a control panel that features the Easy Life system, thanks to which it is possible to carry out a whole welding cycle in a simple, intuitive and repeatable way, so that the operator’s interference would be reduced to the minimum. An built-in memory allows the machine to store 400 welding cycles (including the set diameters and SDR). It is possible to transfer the welding data to a PC through a serial port (USB adaptor connector available) and data-management software. A printer can be connected to the serial port, to get a welding report at the end of each welding cycle.

- A Teflon-coated heating plate with hydraulic movement (in / out) on spherical bearings guides.

- A milling cutter with hydraulic movement (in/out) on spherical bearings guides, operated by an electrical engine, provided with eight steel blades;

- An upper cylinder, to be positioned on the jaws, for welding extra thick pipes and/or whenever it’s necessary to use high pressures.

ON REQUEST (ACCESSORIES)

- Elbows jaws Ø 16" IPS

IPS inserts from Ø 4" to 14"

DIPS inserts from Ø 4" to 14"

- Tees / Crosses / Wyes jaws Ø 12" DIPS

IPS inserts from Ø 4" to 12"

DIPS inserts from Ø 4" to 12"

- Tool for flange necks

- Special milling cutter plates and blades for PVC

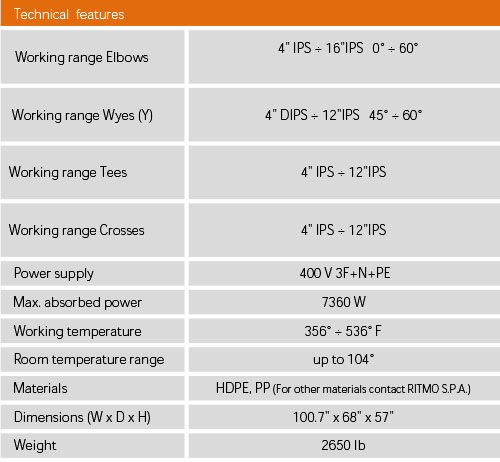

PROFITTINGS 14

PROFITTINGS 14