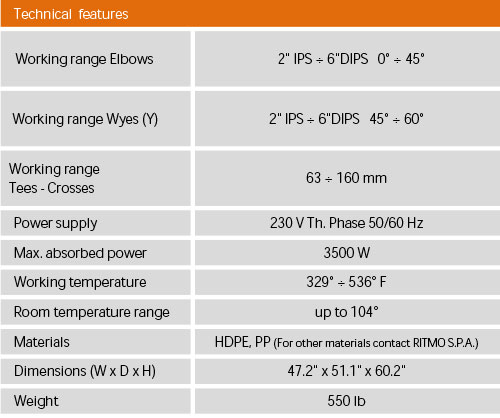

PROFITTINGS 6 is the workshop welding machine designed to fabricate fittings like elbows up to Ø 6" DIPS - 200 mm; Tees, crosses and wyes (Y) up to Ø 6" IPS by joining pipe segments, with the help of special jaws. PROFITTINGS 6 can also weld special and moulded fittings such as elbows, tees and flange necks, thanks to a different type of special jaws.

Composed of:

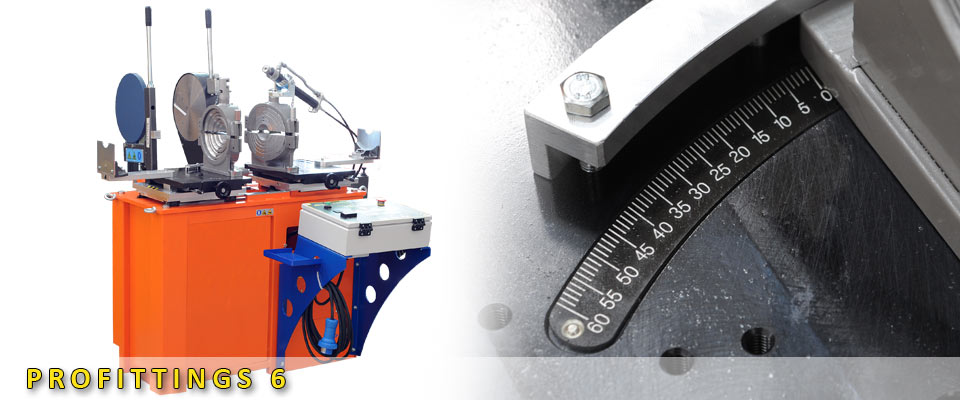

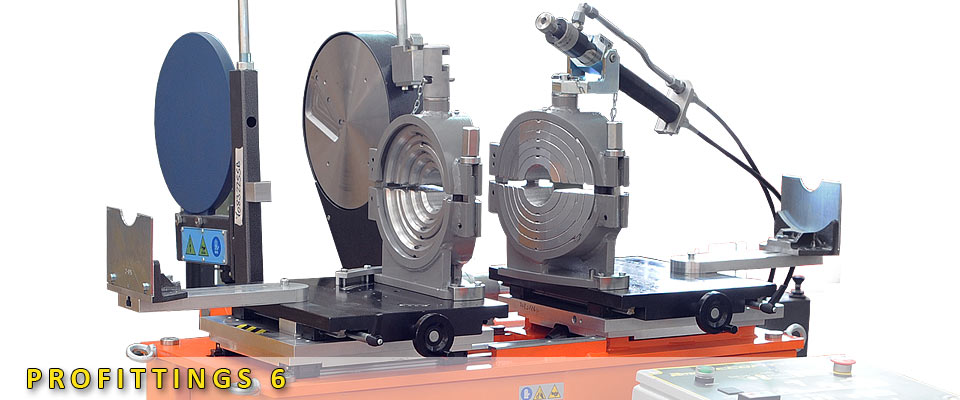

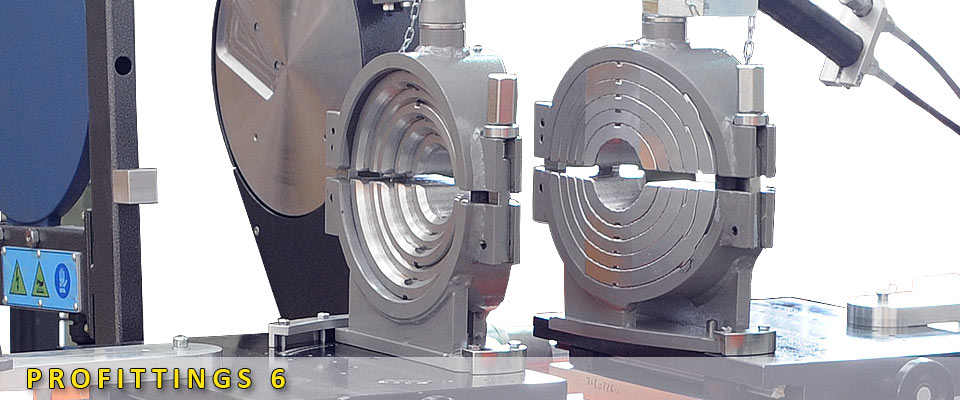

- A machine body with two carriages, one of which driven by a hydraulic system, and two lateral supports with inserts.

- A control panel that features the Easy Life system, thanks to which it is possible to carry out a whole welding cycle in a simple, intuitive and repeatable way, so that the operator’s interference would be reduced to the minimum. An built-in memory allows the machine to store 400 welding cycles (including the set diameters and SDR). It is possible to transfer the welding data to a PC through a serial port (USB adaptor connector available) and data-management software. A printer can be connected to the serial port, to get a welding report at the end of each welding cycle.

- A heating plate with lifting sliding arm.

- An electrically controlled milling cutter for levelling the ends of the pipes and/or fittings with built-in overload cutout and safety microswitch.

- An upper cylinder, to be positioned on the jaws, for welding extra thick pipes and/or whenever it’s necessary to use high pressures.

ON REQUEST (ACCESSORIES)

- Elbows jaws (2 pcs.) Ø 200 mm

IPS inserts from Ø 2” to 6”;

DIPS inserts from Ø 3" to 6";

- Tees / Crosses / Wyes* jawes (4 pcs.) Ø 6” IPS

IPS inserts from Ø 2” to 5” IPS;

DIPS inserts from Ø 3" to 4"

* 1 jaw for elbow is required to fabricate wyes

PROFITTINGS 6

PROFITTINGS 6