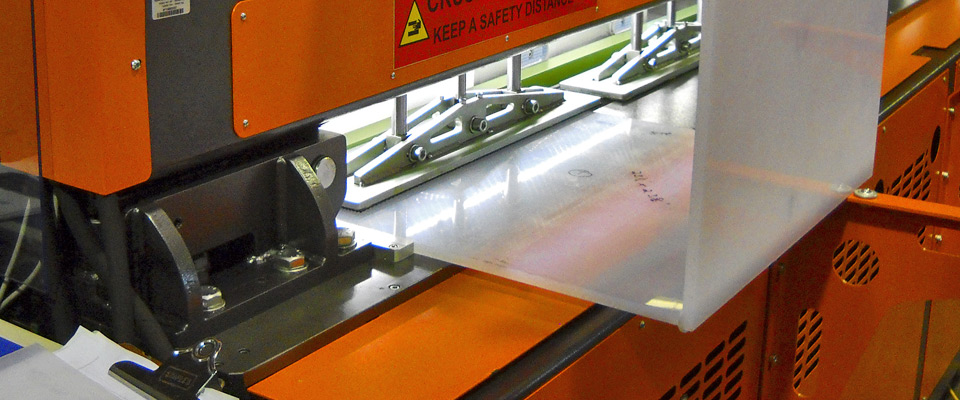

POLYFUSION 3-30, besides operating to weld horizontally, allow you to perform different types of welds as circular and 90° thanks to special accessories available on request. The machine is equipped with a control panel, which allows easily and safely setting and performance of the whole welding process.The butt fusion machine is also able to weld twin-wall HDPE and PP sheets. The machine can operate in compliance with the D.V.S. 2207.

Otherwise according to the user’s needs, it is also possible to input the type of material and the dimension of the thermoplastic sheet, and therefore proceed to weld. It is possible to pre-set 15 customized welding cycles. Each welding cycle is automatically memorized (4000 welding cycles) and it’s possible to save it and transfer the data thanks to an USB storage device.

The butt fusion machine is also able to weld twin-wall PE and PP sheets.

Weldable plastic thickness: 3 ÷ 30 mm the indicated maximum thickness can be welded with materials that require a maximum welding pressure not higher than 0.17 N/mm2; Max. weldable length: 3000 mm.

Welding types: horizontal (standard composition); 90 degrees and circular (on request)

Technical features

Materials

HDPE/PP/PVDF/PVC

Max.working width

3000 mm

Min. weldable thickness

3 mm

Max. weldable thickness

30 mm

Types of welding

Plane, Circular*, 90°

Power supply - Max. absorbed power

400 V - 12500 W

Pneumatic feed (for 90° welding)

Tank 1000 lt – 0.78 m3/h at 6 bar compressor

Memory

4000

Report

PDF

Pre-set customized

15

Dimensions folded brackets

4200 x 1540 x 840 mm

Dimensions unfolded bracket

4200 x 1540 x 1960 mm