CNC welding cycle

Compliant with welding standards DVS 2207

PE (DVS 2207-1); PP (DVS 2207-11); PVC-U (DVS 2207-12); PVC-C (DVS2207-13); PVDF (DVS 2207-15)

Weldable materials: sheet in PVC, PE, PP, PVDF; twin walls in PE and PP.

Welding range 3 ÷ 50 mm (contact RITMO S.P.A for more details) solid wall; max 60 mm twin walls

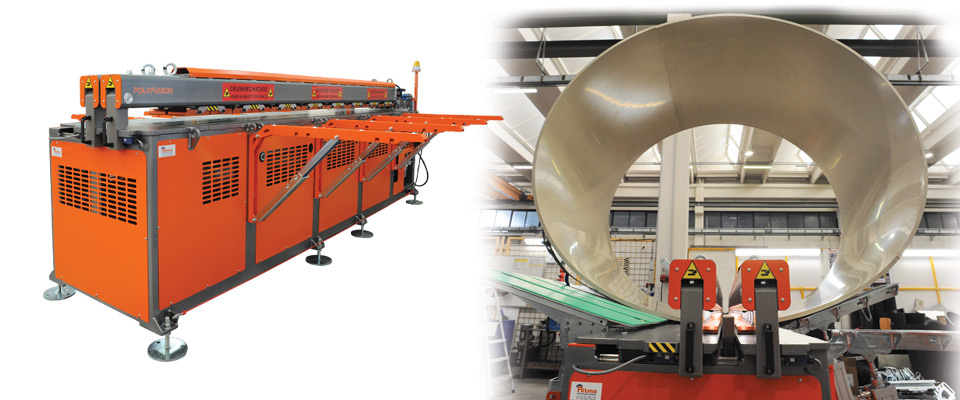

VERSATILE

- Welds up to 3 mt length

- Suitable for small size sheets welding

- Working pressures: nominal 7 bar - maximum 9,5 bar

- Type of butt fusion welding: Straight, 90 ° welding (accessory on request), T welding (accessory on request), Circular welding (accessory on request)

PRECISE

- High density locking clamps that provide an homogeneous pressure distribution

- Led lights throughthe entire welding area

- Graduated scales to set the sheet in position

- Constant stabilizing pressure control

- Additional overboost

- Unlimited store of welding report

- Unlimited store of pre-setting parameters and possibility to recall them

- Welding cycles management according to the standards or customizable

Pre-set welding standards: - PE (DVS 2207-1) - PP (DVS 2207-11) - PVC-U (DVS 2207-12) - PVC-C (DVS2207-13) - PVDF (DVS 2207-15)

Twin wall pre-set parameters on suggested values: PANELTIM - RÖCHLING - SIMONA

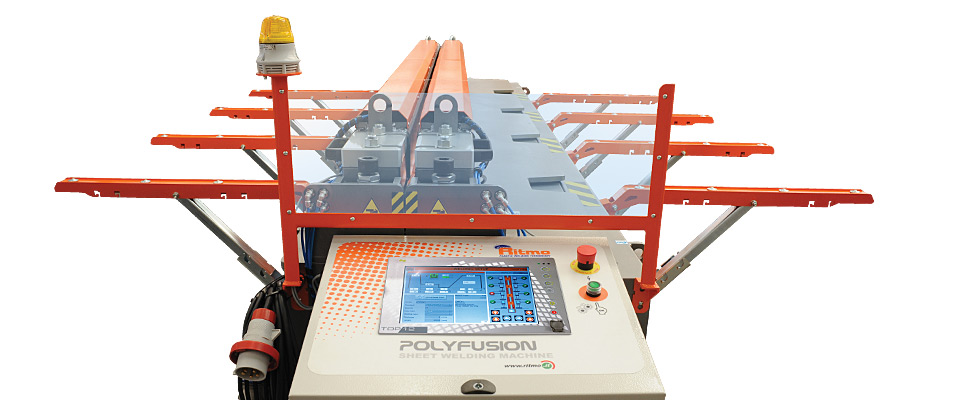

COMPLETE

- 4 independent welding areas

- CNC welding cycle

- Pre-setting store and recall parameters

- PLC control panel

- 12” touch screen

- Remote control and analysis

- Diagnostic feature

- Upgradable Software via USB

Standard composition:

- Folding lateral supports with bearing balls for the easy sheet movements

- High density of locking clamps: they provide an homogeneous pressure distribution capable of stopping both large and thin thicknesses sheets, and working with long or short sheets

- Led lights through the entire welding area

- New Ritmo “AirPlus” system allows to complete a welding cycle even in the event of an unexpected fault of the air supply in your building

- A PLC control panel allows the operator to program the working cycle quickly with the help of an intuitive touch screen

- The “Adjusty” system automatically adjusts the distance between heating plate and machine edge according to the thickness of the sheets. With thin sheets the system permits a welding without overlapping while for thick sheets enough space for the bead is guaranteed

- Internal memory for unlimited number of welds

- Download report in CSV format

- USB port

- Unlimited welding pre-setting (customized or preferred) easy to be recalled

- Wide range of optionals and accessories to expand its functionality

Technical features

Materials

PE/PP/PVC-C, PVC-U, PVDF

Max.working width

3050 mm

Weldable thickness solid wall

3 ÷ 50 mm (contact Ritmo S.P.A. for details)

Weldable thickness twin walll

up to 60 mm

Types of welding

Plane, 90°, T, Circular*

Power supply - Max. absorbed power

400 V - 11500 W

Minimum requirements pneumatic supply

7 bar capacity= 300 l/min

Memory

Limitless

Report

CSV limitless

Pre-set welding standards

yes

Weight

2550 Kg

Dimensions unfolded bracket

4307 x 2673 x 1508 mm

The minimum diameter is calculated based on the geometric characteristics of the machine. The range of diameters that can be produced and their thickness are bound to the use of external systems such as overhead cranes, forklifts etc. and the permissible strain of the outer fibers of the material. Refer to the material datasheet of the manufacturer for further information in this regard.