REMEDY 1000 EL is an independent, high-productivity welding machine driven by tracks and powered by a Diesel 3.6-cylinder in-line Turbo-Common Rail on-board generator.

The machine designed for butt-welding HDPE and PP pipes up to Ø 1000 mm for the transportation of water, gas and other fluids under pressure. The machine can weld according to ISO 21307 High Pressure and ASTM F2620 standards.

- Working range from Ø 355 to 1000 mm

- EASY LIFE welding system that allows the operator to program and control the machine welding cycle in a simple, fast and intuitive way. The system incorporates a data-logging for welding data record and a GPS for traceability data storage. The internal memory allows to record up to 4000 welds (including diameter and SDR settings) and to download them in PDF via USB port. The welding machine memory can store up to 20 customized working parameters for immediate recall.

- The machine body it’s easily removable from the tracks so to be able to work in confined spaces. An extension kit for working in the ditch is available on request. It is also possible to disconnect the welding machine from its generator and connect it to an mainline or another external generator.

- Hydraulic system for opening and closing the clamps.

- Electrohydraulic milling cutter on board with safety microswitch and hydraulic movement on the machine

- Heating plate with hydraulic movement on the machine, coated with Teflon (PTFE) and supplied with a high temperature resistant casing, which prevents the plate from being damaged by scratches.

- Terrain and slope: drives up to 35% slopes

- Remote tracks control for driving the machine on ground (up to 100m range).

- Control panels for the hydraulic movement of the hotplate cutter and lateral roller. Controlled by intuitive and practical levers.

- Removable Easy Life welding cycle panel with graphic display.

- Hydraulic side rollers to facilitate pipe loading and handling.

- Raised working position with platform for working and operating comfortably.

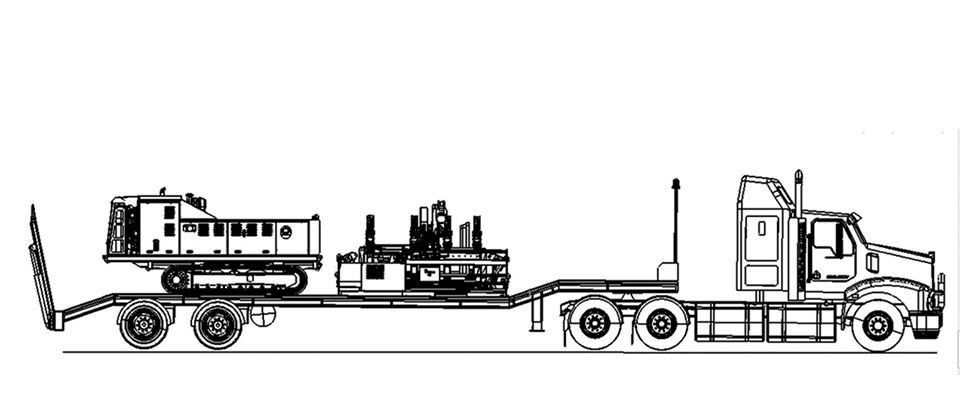

- Adjustable width between tracks for easy transportation.

- REMEDY 1000 EL is able to weld fittings such as bends, tees, branches and collars for flanges.

ON REQUEST (ACCESSORIES)

- Clamps’ inserts from Ø 335 to 900 mm; 14" ÷ 36" IPS; 14" ÷ 36 " DIPS

- Tool for flange necks

- Kit for IN-DITCH use

- Kit hoist

The machine designed for butt-welding HDPE and PP pipes up to Ø 1000 mm for the transportation of water, gas and other fluids under pressure. The machine can weld according to ISO 21307 High Pressure and ASTM F2620 standards.

- Working range from Ø 355 to 1000 mm

- EASY LIFE welding system that allows the operator to program and control the machine welding cycle in a simple, fast and intuitive way. The system incorporates a data-logging for welding data record and a GPS for traceability data storage. The internal memory allows to record up to 4000 welds (including diameter and SDR settings) and to download them in PDF via USB port. The welding machine memory can store up to 20 customized working parameters for immediate recall.

- The machine body it’s easily removable from the tracks so to be able to work in confined spaces. An extension kit for working in the ditch is available on request. It is also possible to disconnect the welding machine from its generator and connect it to an mainline or another external generator.

- Hydraulic system for opening and closing the clamps.

- Electrohydraulic milling cutter on board with safety microswitch and hydraulic movement on the machine

- Heating plate with hydraulic movement on the machine, coated with Teflon (PTFE) and supplied with a high temperature resistant casing, which prevents the plate from being damaged by scratches.

- Terrain and slope: drives up to 35% slopes

- Remote tracks control for driving the machine on ground (up to 100m range).

- Control panels for the hydraulic movement of the hotplate cutter and lateral roller. Controlled by intuitive and practical levers.

- Removable Easy Life welding cycle panel with graphic display.

- Hydraulic side rollers to facilitate pipe loading and handling.

- Raised working position with platform for working and operating comfortably.

- Adjustable width between tracks for easy transportation.

- REMEDY 1000 EL is able to weld fittings such as bends, tees, branches and collars for flanges.

ON REQUEST (ACCESSORIES)

- Clamps’ inserts from Ø 335 to 900 mm; 14" ÷ 36" IPS; 14" ÷ 36 " DIPS

- Tool for flange necks

- Kit for IN-DITCH use

- Kit hoist

Technical features:

| Materials | HDPE/PP |

| Working range |

Ø 335 ÷ 1000 mm 14" IPS ÷ 36" IPS/DIPS |

| On board generator * | 3600 cc - 85 Kw 2300 Rpm |

| Fuel | Diesel |

| Fuel tank | 160 litres (42.2 gal) |

| Autonomy min. | 10h 30' |

| Weight tracks and generator | 5500 Kg (12.125 lb) |

| Total weight | 9200 Kg (20.280 lb) |

|

Body machine sizes Max dimentions on site (H X W X D) |

2817 x 3530 x 3370 mm 9.2 x 11.5 x 11 ft |

| Body machine + tracks, platform max dimentions on site (H X W X D) |

3496 x 4424 x 2780 mm 11.4 x 14.5 x 9.4 ft |

| Tracks dimentions (H X W X D) |

2159 x 4424 x 2220 mm 7 x 14.5 x 7,2 ft |

* The welding machine is independent, has a generator on board and does not require an external power supply.

However, it is possible to connect an external generator to the machine body only. Recommended power 42000 W14" IPS ÷ 36" IPS/DIPS